Getting Heavy-Duty Vehicle Fleets to Net-Zero

Insights into how fleet owners make environmental decisions

Vehicles that weigh more than 10,000 pounds, such as trucks and buses, are considered “heavy-duty.” Heavy-duty vehicles pollute a lot: They are only 3.5% of all vehicles, but account for 24% of the greenhouse gas emissions from the U.S. transportation sector. They also disproportionately emit other pollutants. These emissions make it essential to find cleaner and more sustainable fuels for these vehicles. To that end, California has adopted ambitious targets (under Executive Order N-79-20) to replace all heavy-duty vehicles with zero-emission vehicles by 2045. This will be a difficult goal to meet. In 2020, alternative fuel vehicles — including those with zero emissions or running on fuels cleaner than petroleum — accounted for less than 3% of all the heavy-duty vehicles in California. Just 0.2% of these vehicles were emission-free.

These numbers are disappointingly low, and they cannot be explained by alternative fuels being completely unavailable. There are many alternative fuels on the market today: compressed natural gas, liquefied natural gas, propane, electricity, hydrogen, E85, biodiesel, and renewable diesel, among others. Not all are available for every specialized heavy-duty vehicle (e.g., some might work for school buses but not trash trucks), but virtually every type of heavy-duty vehicle has a clean fuel option. The low uptake of these fuels underscores the importance of understanding why organizations that operate these vehicles are not adopting clean fuel vehicles on their own.

My colleagues and I studied the adoption decisions of these fuels, made by people who operate heavy-duty vehicle fleets. We collected data from 20 fleet operators in California, from both the private and public sectors, and asked how they chose whether or not to implement alternative fuel vehicles. The organizations we studied operated various types of vehicles, including transit and school buses, waste collection trucks, local delivery and freight trucks, tractors, dump trucks, and tanker trucks. The fleet size also varied, with the smallest being 10 construction trucks and the largest more than 2,400 trucks and buses of different types. In 29 cases, these organizations had considered an alternative fuel and switched to them, and in 42 cases they had considered one and decided not to switch (the number of cases exceeds the number of operators because many operators have considered more than one kind of fuel).

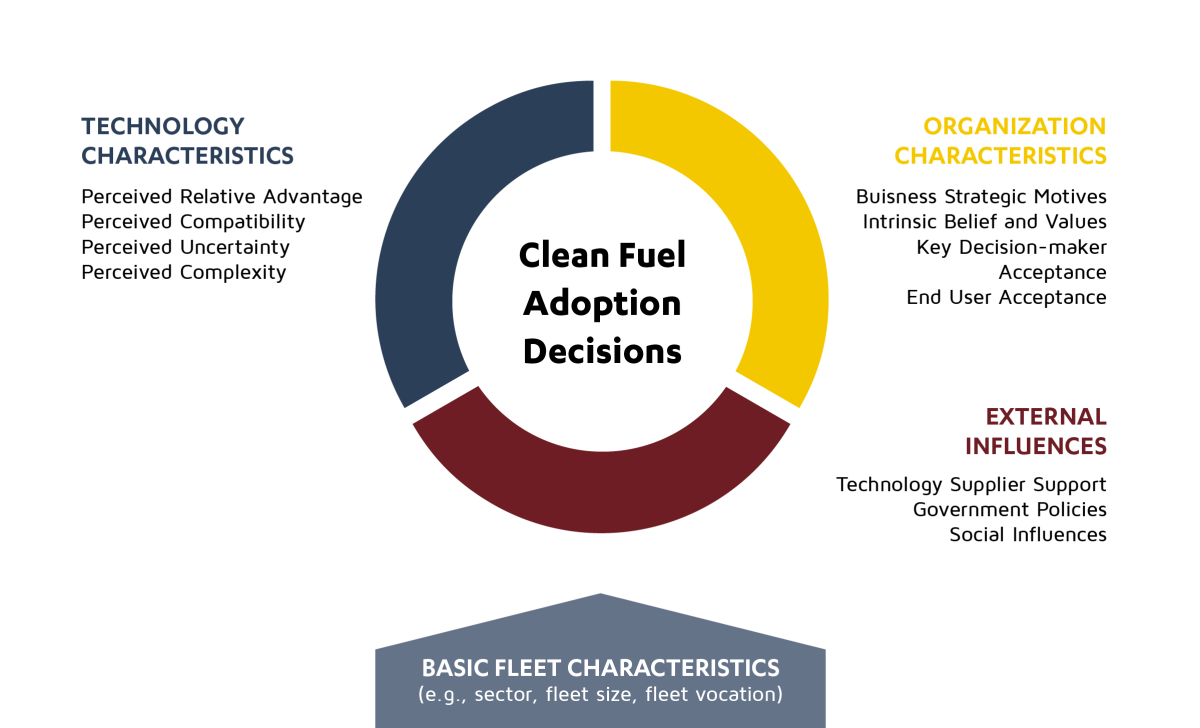

As shown in Figure 1, we group the factors that influenced the fleet operators’ decisions into three main categories: technological considerations, organizational characteristics, and external influences.

Technological considerations include whether a fuel technology is actually compatible with the work an operator needs to perform; how hard the fuel technology is to understand and use (e.g., how complicated is it to charge or refuel?), the level of uncertainty and risk involved in using it (e.g., will the fuel or the company be around in five years? How far can a vehicle go on a single charge or tank?), and the relative advantages and disadvantages of using the vehicles (e.g., will the operator save money?).

Organizational characteristics include specific business strategies that might make an operator more willing to change fuels, including commitment to intrinsic beliefs and values like corporate social responsibility, and the personal attitudes of both key decision-makers (like company executives) and rank-and-file drivers (who may be more or less accepting of new vehicles).

Lastly, external influences include the supportiveness of the firms supplying the technology, as well as government policies like regulations and incentive programs, and direct or indirect social influence from others in society and the industry.

Figure 1. Framework for Adoption Decisions of Clean Fuel Vehicles in Heavy-Duty Fleets

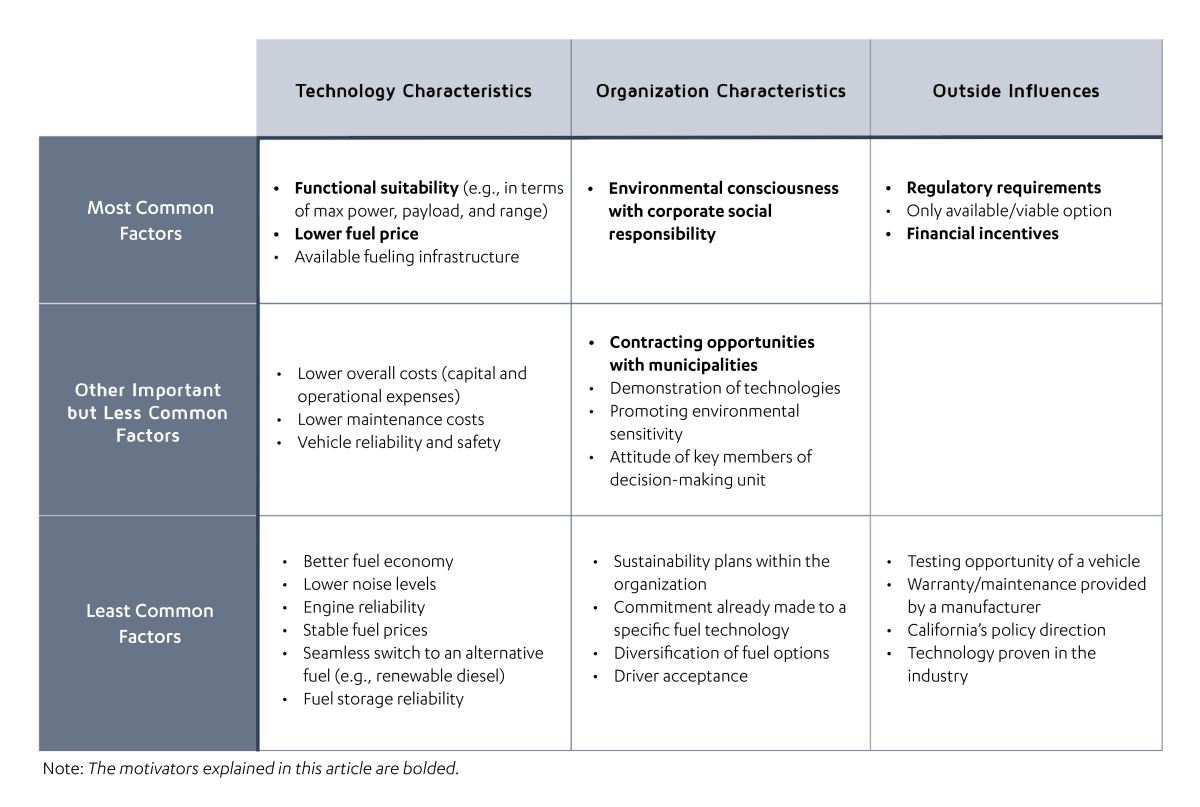

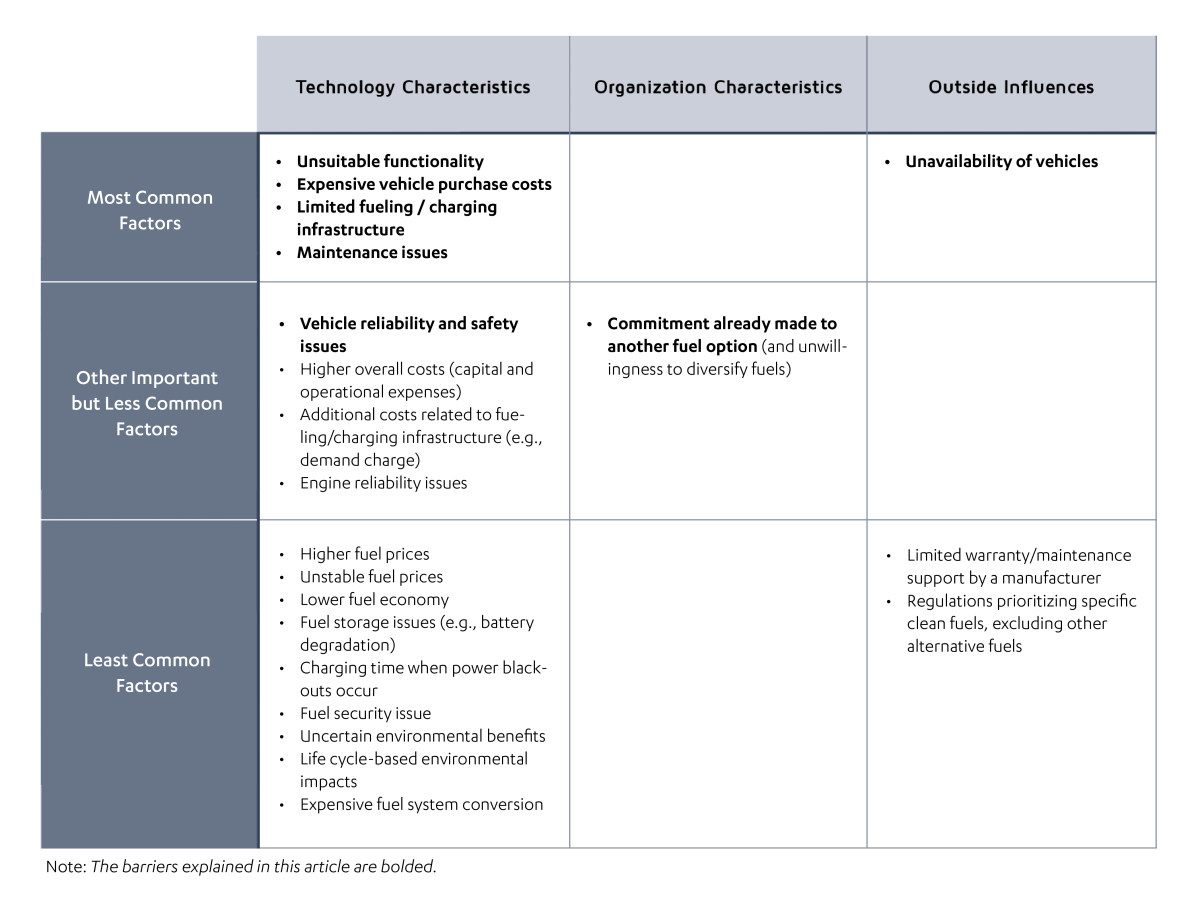

The organizations we interviewed discussed various factors that influenced their decisions to adopt or reject specific types of alternative fuel vehicles. The major motivators included a strong sense of corporate social responsibility and environmental consciousness, financial advantages gained from lower fuel prices, and the need to comply with government regulations (see Table 1). On the other hand, the prominent obstacles that made them hesitant to adopt included vehicle unavailability in the market, unsuitability of the vehicles for the organization’s specific work, high purchasing costs, and limited fueling/charging infrastructure (see Table 2).

Table 1. Motivators for Adopting Clean Fuels for Heavy-Duty Vehicles

Table 2. Barriers to Adopting Clean Fuels for Heavy-Duty Vehicles

Motivators for Adopting Clean Fuel Technologies

Operators were motivated by a range of justifications — some more altruistic than others. Many public and private organizations expressed a strong sense of environmental responsibility as a key motivator to invest in clean fuel technologies. Our interviews revealed that these organizations, which chose to use clean fuels, were aware of the harmful effects of emissions from diesel vehicles. While they recognized certain technological and financial barriers to adopting cleaner fuels, such as limited infrastructure and higher vehicle purchase costs, their environmental concerns drove them to purchase clean fuel vehicles.

Cost considerations also played a role. The fleet operators we interviewed repeatedly mentioned that some clean fuels, particularly compressed natural gas and electricity, were priced lower than traditional diesel. For example, over half of the adopters of compressed natural gas vehicles highlighted their lower fuel prices, which can help reduce operating costs and, in turn, lower total costs of ownership.

Government regulations were also an influence, particularly in cases where clean fuels were not cost-competitive. One organization noted that without regulations, they would not use alternative fuels, and would instead save money by using lower-cost diesel.

Explicit financial incentives also play a role. Incentives can reduce what would otherwise be very high upfront costs of switching fuels: buying new vehicles and constructing fueling/charging facilities in areas with limited infrastructure. Many fleet operators who switched fuels said that incentive programs were instrumental in their decision to do so, as these programs helped offset the price difference between clean fuel vehicles and diesel vehicles. Several operators further highlighted that, without financial incentives, it would be challenging to acquire alternative fuel vehicles, or at least, it would slow down the process of replacing their diesel vehicles.

A few operators also mentioned long-term business strategy; in California, being green-friendly can help firms win lucrative contracts. Operating clean fuel vehicles is an advantage when firms are seeking contracts with municipalities that are more receptive to ecologically sustainable fleets.

Barriers to Adopting Clean Fuel Technologies

The most common reason for a fleet operator to decide against alternative fuels was that the commercially available technology did not seem suitable for the particular application the operator needed. For example, electric heavy-duty vehicles were often ruled out for certain applications due to range or power incompatibility.

Purchase costs also played a large role. The price of clean fuel vehicles is often higher than that of conventional diesel vehicles. A hydrogen transit bus costs around $1.3 million, compared to $890,000 for an electric bus, $560,000 for a compressed natural gas bus, and $480,000 for a diesel bus. If the high purchase cost did not make financial sense to an organization, or if they could not defray it sufficiently with a government incentive, they considered that fuel option a “non-starter” when making their decisions.

Limitations in fueling or charging infrastructure were also a significant barrier. In situations where the available off-site fueling stations were far from an operator’s depots or fleet routes, switching to that fuel would require not just changing vehicles but also changing routes and schedules. To avoid this complication, many operators try to avoid relying on off-site stations, and prefer to construct their own fueling/charging stations on-site. But such stations are expensive, even assuming there is room for them.

Reliability, including maintenance and safety issues, was also a significant barrier for certain technologies. Some fuel types, such as compressed natural gas and liquified natural gas, were more expensive to maintain, and in certain circumstances unsafe for certain uses. Fuels that must be kept under pressure or under temperature conditions (e.g., compressed or liquified natural gas) add a layer of complexity to vehicle operations and can increase maintenance costs.

The low uptake of alternative fuels underscores the importance of understanding why organizations that operate heavy-duty vehicles are not adopting clean fuel vehicles on their own.

Strategies for Promoting Clean Fuel Technologies

To achieve environmental policy goals at the local, state, and national levels, governments and technology providers should make greater efforts to help fleet operators of heavy-duty vehicles smoothly shift toward clean fuel technologies — but this transition is challenging. Not only must fuel and vehicle technologies be fully developed, but fleet operators must also be ready to adopt them. To support the adoption of clean-powered fuels policymakers should:

Promote education and outreach. Zero-emission fuel technologies are rapidly advancing, yet some fleet operators may have incorrect or outdated perceptions about their benefits and drawbacks. These misconceptions may include concerns about limited driving ranges or a lack of information about available vehicle models. Targeted educational programs can empower fleet decision-makers and dispel these misunderstandings.

Create opportunities for trials of clean fuel vehicles. By providing firsthand experience, fleet decision-makers can assess the tangible benefits of adopting such vehicles.

Provide support for technology suppliers. There are a number of weaknesses specific to certain heavy-duty clean fuel technology, including limited range of electric buses and insufficient power and payload capacity of electric hauling trucks. It is vital that governments provide research and development assistance to support technology suppliers, including vehicle manufacturers and fuel providers, to address and overcome these technological challenges.

Continue and enhance financial support for fuel transitions. It is important to continue providing financial incentives. These incentives can include substantial offsets for higher initial purchase costs, particularly for those who are sensitive to vehicle purchase costs, and life-cycle ownership costs.

Improve support for constructing on-site fueling/charging facilities. In the current stage of the market, fleets tend to build their own charging facilities. However, building these facilities can be complex, requiring technical guidance and substantial financial support.

It is crucial to provide fleets with a clear and stable long-term vision of the benefits of investing in alternative fuels, along with comprehensive financial and technical support. Doing so can facilitate widespread adoption in the long run, and ultimately ensure greater environmental and health benefits from reduced emissions.